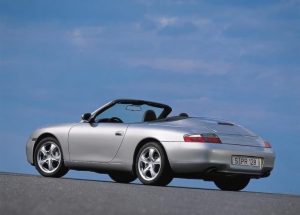

Recalls: Porsche 996 911 Cabriolet

Overview

Manufacturers, or importers, issue recalls for defects or faults which have the potential to cause injury. Generally, manufacturers will inform the original buyers if their vehicle is subject to a recall and of the steps required to remedy the defect or fault. Please note that the recalls below (if any) are for Australian-delivered vehicles only. Furthermore, the number of recalls should not be taken as an indication of a model’s reliability or its safety more generally.

Recalls: Porsche 996 911 Cabriolet

- In May 2004, a recall was issued for 2003 model year Porsche 911 Cabriolet Carrera, Carrera 4 S and Turbo variants that were manufactured prior to 17 March 2003. In these vehicles, the front seats lacked the rigidity required by Porsche due to a supplier manufacturing error. In the event of a rear-end collision, the seatbacks of occupied front seats could tilt on one side to the rear (PRA 2004/6987).

Problems and faults: Porsche 996 911 Cabriolet

Overview

This section identifies potential problems, causes and fixes based on the experiences of owners and repairers, online sources and technical service bulletins. This information is provided solely for reference purposes and AustralianCar.Reviews recommends that only properly qualified persons carry out repairs or modifications. Furthermore, the number of items below should not be taken as an indicator of a model’s reliability or the frequency with which they may occur.

To report a problem or fault to the AustralianCar.Reviews team, please use the Contact Us form. Note that AustralianCar.Reviews does not offer advice on automotive problems or disputes; such enquiries will not receive a reply. For vehicles purchased from dealers after 1 January 2011, please see our Australian Consumer Law fact sheet.

Porsche 996 911 Carrera: M96 engine and Intermediate shaft bearing (IMS bearing) failure

About the Intermediate Shaft (IMS) bearing

For Porsche’s M96 and M97 engines, the timing chains are driven off opposite ends of the intermediate shaft. The suspect Intermediate Shaft bearing is located at the flywheel end of the motor and handles the majority of the load on the intermediate shaft. Due to the design of the crankcase, however, there are no internal oil passages from which pressurised engine oil can be used to lubricate this bearing.

Intermediate Shaft bearing failure

It is understood that there are two causes of Intermediate Shaft bearing failure:

- Over time, oil and contaminants may seep past the bearing seal, wash out the original lubricant and become trapped inside it – this causes the bearing to overheat, wear prematurely and eventually fracture; and,

- On early M96 engines, the centre bolt that was used to secure the IMS bearing was too weak and could snap, causing the bearing to fail.

If the Intermediate Shaft bearing fails,

- Contaminants and debris from the bearing can circulate throughout the engine. If this occurs, the engine has to be dis-assembled and rebuilt; and,

- The timing chains can disengage such that the pistons and valves collide, causing serious damage that requires the engine to be replaced.

Intermediate Shaft bearing revisions

During production of the M96 and M97 engines, the intermediate shaft was revised twice –

- Original design – M96 engine (from 1997-99 model years): a dual-row ball ball-bearing. While all M96 engines from the 1997 to 1999 model years had this dual-row ball-bearing, it continued to be used in some 2000 and 2001 engines. It has been estimated that the intermediate shaft bearing failure rates for these M96 engines is 4 to 7 per cent.

- First revision – M96 engine (from 2000-01): a single row ball-bearing with a reduced load capacity. By model year 2002, all engines used this smaller, lower capacity bearing. It has been estimated that the intermediate shaft bearing failure rates for these M96 engines is around 10 per cent.

- Second revision – M97 engine (2005-08 model years): a much larger single row bearing was introduced which had the same load capacity of the early dual-row ball bearings. This revision, however, could not be serviced without engine dis-assembly so that the IMS bearing could not be replaced as a preventative measure.

In all designs, however, Porsche continued to use a sealed ball-bearing and did not specify a service interval for their replacement.

Symptoms

The seal around the intermediate shaft cover was susceptible to leaks, but was subsequently revised. If there are oil leaks in this area, then the intermediate shaft may be failing and should be inspected immediately.

The oil filter should be regularly inspected for signs of metallic debris (from the metal balls within the bearings) that are indicative of a deteriorating IMS bearing.

Prevention

To reduce the likelihood of an IMS failure, it is recommended that:

- The engine oil be changed every 6 months or 6000-8000 kilometres. This prevents higher acid levels in the oil which can destroy the bearing seals; and,

- The vehicle be driven regularly and engine speed kept above 2500-3000 rpm. It is understood that higher engine speeds unload the IMS bearing and aid in lubrication.

For model year 1997 to 2005 engines, the IMS bearing is accessible and a replacement bearing can be installed as a preventative measure (see Pelican Parts’ IMS Bearing Replacement article); there are also a range of aftermarket options available from IMS Solution and LN Engineering.

Porsche 996 911: rear main seal (RMS) failure and oil leaks

For M96 engines in the Porsche 986 Boxster, 996 911 and 997 Series I 911, the rear main seal (i.e. the oil seal that fits around the output end of the crankshaft) can leak oil into the transmission’s bell housing. If not detected early, the oil can damage the flywheel and clutch. Many owners, however, only become aware of this problem when oil starts leaking onto the surface below the vehicle. It has been speculated that the leaks were due to casting variations where the seal was located; while some were circular, others had an oval shape.

It is understood that Porsche have changed the design of the seal a number of times during production from 1996 to 2008. While the original seal was rubber and had a spring ring, later seals had a solid metal insert within the rubber for greater stiffness. The fourth generation seal came with a green plastic installation ring to protect the sealing lip as the seal was pressed into place; the plastic ring would then be removed. However, the revised seal would not fit on the old intermediate shaft cover since the seal was wider than the original; as such, the cover had to be replaced to fit the revised seal.

To replace the seal, the gearbox and clutch have to be removed. To properly fit the seal, the correct Porsche tool should be used to press it in. While some repairers may try to tap it in with a hammer, this poses a risk of damage and not properly aligning the seal; it may also push the seal too far into the engine.

In March 2003, a new tool was introduced to set the seal further into the bore than the original seal for improved sealing against an area that does not have wear and is free from corrosion. Since the rear main seal (RMS) is a lip-type radial seal, it must exert radial pressure on the crankshaft sealing journal. Over time, the seal wears a small groove into the crankshaft journal.

Problems and faults: Porsche 996 911 Cabriolet

- The radiators in the front of the vehicle are made from thin aluminium which is susceptible to corrosion and damage from stone chips – these can affect the engine’s supply of coolant and the air conditioning system.

- For models with manual transmissions, the clutch pedal may return slowly or incompletely due to a loose clip on the hydraulic line.

- The convertible roof may not close due to a faulty micro-switch in the lift mechanism.

- The door may not open from the inside due to a broken cable between the handle and the release.

- For models with turbocharged engines, the engine may lose power due to a loose pressure hose between the turbochargers and the intercooler.

- The fuel gauge may provide inaccurate readings and there may be difficulties when refueling due to a rubber fuel line inside the tank interfering with the sending unit or filler neck flap.