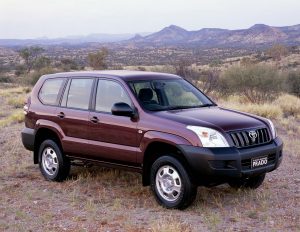

Recalls: Toyota 120-Series Landcruiser Prado

Overview

Manufacturers, or importers, issue recalls for defects or faults which have the potential to cause injury. Generally, manufacturers will inform the original buyers if their vehicle is subject to a recall and of the steps required to remedy the defect or fault. Please note that the recalls below (if any) are for Australian-delivered vehicles only. Furthermore, the number of recalls should not be taken as an indication of a model’s reliability or its safety more generally.

Recalls: Toyota 120-Series Landcruiser Prado

2002-03 Toyota GRJ120 Landcruiser Prado: fuel pulsation damper

In April 2003, a recall was issued for Toyota 120-Series Landcruiser Prado models manufactured from 29 October 2002 to 22 March 2003 due to improper assembly of the fuel pulsation damper; the fuel pulsation damper was responsible for reducing fuel pulsation generated by the fuel injectors (PRA 2003/6123).

Problems and faults: Toyota 120 Landcruiser Prado

Overview

This section identifies potential problems, causes and fixes based on the experiences of owners and repairers, online sources and technical service bulletins. This information is provided solely for reference purposes and AustralianCar.Reviews recommends that only properly qualified persons carry out repairs or modifications. Furthermore, the number of items below should not be taken as an indicator of a model’s reliability or the frequency with which they may occur.

To report a problem or fault to the AustralianCar.Reviews team, please use the Contact Us form. Note that AustralianCar.Reviews does not offer advice on automotive problems or disputes; such enquiries will not receive a reply. For vehicles purchased from dealers after 1 January 2011, please see our Australian Consumer Law fact sheet.

Toyota 120 Prado: 1KZ-TE overheating

Overheating of the 1KZ-TE engine requires urgent attention since it can cause the cylinder head to crack. Overheating may be caused by:

- Failure of the viscous fan hub – this is generally noticed by temperatures rising when ascending hills or during stop/start traffic on hot days;

- Blockage of the radiator;

- Seizure of the wastegate actuator resulting in overboost;

- A hole in the heater hose; and,

- Too much load on the cooling system – a worn torque converter may contribute to this.

To improve the cooling system, common modifications for the LandCruiser Prado upgrading the radiator and fitting larger exhaust systems.

Toyota 120 Prado: 1KZ-TE cracked cylinder head

As a result of overheating, the 1KZ-TE engine is susceptible to cracked cylinder heads. Symptoms of a cracked cylinder head include:

- Small bubbles in coolant system, pushing coolant into the overflow bottle;

- Consumption and discolouration of coolant;

- Rapid overheating;

- Rough running; and,

- A loss of power.

If the cylinder head has cracked, the turbocharger is susceptible to overheating – this may cause excessive movement of the shaft and allow the blades to hit the housing. It is recommended that the cylinder head be replaced with a genuine Toyota head since there have been reports of casting faults in non-genuine products.

Please note that pressure testing the cylinder head does not always reveal a problem.

2006-09 Toyota 150 LandCruiser Prado: 1KD-FTV cracked pistons

For 2006-09 Toyota 120-Series LandCruiser Prado (KDJ120/KDJ125) vehicles with 3.0-litre 1KD-FTV engines that comply with Euro IV emissions standards, the pistons are susceptible to cracking. While the size of the cracks varies, they can amount to a localised rupture. In affected vehicles, piston cracking is most common between 100,000 km and 150,000 km. Issued in September 2014 by Toyota, Technical Service Bulletin EG-008T-0112 acknowledged the problem of cracked pistons for the Euro IV 1KD-FTV engine.

Symptoms of a cracked piston include:

- A sudden, strong knocking noise from the engine;

- Black smoke from the exhaust;

- A loss of power;

- The engine ‘running rough’ (i.e. on 3 cylinders); and,

- Excessive crankcase pressure.

The pre-Euro IV 1KD-FTV engines did not experience this problem because the piston had a metal fibrous structure fused into the piston crown. The piston design, however, was changed for the Euro IV 1KD-FTV engine.

To reduce the risk of cracked pistons in a Euro IV 1KD-FTV engine, it is recommended that:

- The engine not be subjected to chip tuning;

- The vehicle not be driven for under load for extended periods; and,

- That the fuel injectors are serviced every 100,000 kilometres.

While these measures will reduce the likelihood of failure, they do not rectify the design fault of the pistons.

According to the technical bulletin, two production changes – ‘improved injectors to prevent wrong combustion’ and more robust pistons – were implemented in 2014. Despite these changes, however, cracked pistons have been reported in revised vehicles (although the failure rate is lower).

2005-07 Toyota 120 Prado with 1KD-FTV engine: injector seal failure

Initially, the 1KD-FTV engine had copper seats at the base of the common rail injector to provide a seal against the combustion chamber.These seats, however, can fail and cause the following problems:

- Blow-by gases enter the tappet cover and mix with the engine oil – this bakes and carbonises the engine oil;

- Blow-by gases block the oil sump pick-up;

- The engine can be starved of oil;

- The lack of lubrication cause excessive friction and heat, causing the bottom end bearings to melt and engine failure.

Symptoms of a failed common rail injector seal include:

- White smoke and a rattling noise after a cold start; and,

- A blocked oil sump pick-up.

AustralianCar.Reviews understands that new aluminium seats were introduced for the 1KD-FTV engine from August 2007. AustralianCar.Reviews recommends that owners of vehicles with the 1KD-FTV engine which have copper injector seats have them replaced with the updated injectors and the oil sump pick-up cleaned if there is evidence of the copper injector seats allowing blow-by gases to pass. At each service, the oil sump pick-up should be inspected and, if required, cleaned by removing the oil sump covers, taking out the screen and spraying it with a carbon cleaner or degreaser.

For further information, please see pradopoint.com and What Causes the Hilux and Prado Clogged Oil Sump Pickup?

Toyota 120 Prado with 1KD-FTV engine: injector failure

It is not uncommon for the injectors in the 1KD-FTV engine to fail around 120,000 to 140,000 kilometres, though they may fail as early as 75,000 kilometres or last 250,000 kilometres. Symptoms of a failing injector include:

- A loud ‘knock’ noise that is audible when the windows are down, particularly when the engine is cold;

- Poor fuel economy;

- An erratic or rough idle; and,

- Rough running, particularly under load at low engine speeds

The shorter lifespan of these injectors is attributable to the high fuel pressure (from 30 to 160 MPa), multiple injections per combustion stroke, small tolerances and fuel quality. As a preventative measure, it is recommended that the injectors be replaced every 100,000 kilometres. At each service, it is recommended that a diagnostic test be conducted to measure feedback volumes or total volumes for the injectors to see if they are working properly.

Toyota 120 Prado: CV joints and boots

The front axles have four ‘constant velocity’ or CV joints: two inboard and two outboard. The CV joints are encased by rubber boots that maintain the CV joints’ supply of grease on the inside and protect against dirt and water ingress. Over time, however, the boot may develop cracks or splits which allow foreign material to enter and damage the CV joint. Symptoms of cracked or split CV boots include:

- A greasy or oily substance on the surface below the vehicle or around the front wheels; or,

- Abnormal clicking noises while driving.

While the driveshaft and CV joint normally have to be removed to replace a boot, the Toyota split boot kit can be fitted without removing the driveshaft.

Other problems and faults

- The automatic transmission oil coolers are located in the engine radiator, such that cracks in the oil coolers can result in engine coolant entering the transmission.

- The rear suspension height sensors are susceptible to failure.