[su_image_carousel source=”media: 52267,52268,52269″]

Introduction

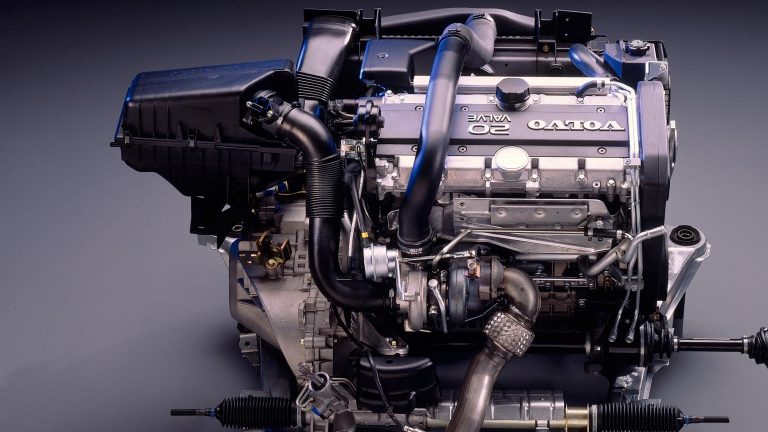

Volvo’s ‘N Series’ engines were a range of modular inline four-, five- and six-cylinder engines that were manufactured in Skövde, Sweden. The first N Series engine was the longitudinally mounted six-cylinder B6304F which powered the rear-wheel drive Volvo 960. The four- and five-cylinder N Series engines, however, were mounted transversely.

The first five-cylinder N Series engine was the B5254F which was introduced in June 1991 for the Volvo 850. The B5254F engine was the first five-cylinder engine to be mounted transversely for a front-wheel drive vehicle and introduced the Volvo Variable Intake System (V-VIS, described below), though this was discontinued after 1994. In 1995, the N Series range expanded to include four-cylinder engines – the B4814S and B4204S – which were developed for the Volvo S40.

In 1998, Volvo introduced its ‘Revised N’ (RN) engine which progressively replaced the N Series engine.

Common attributes of Volvo’s N Series engines

Common attributes for the N Series engines included:

- A cylinder block and lower crankcase manufactured from high-pressure die-cast aluminium, featuring a reinforcing ribbed structure and cast in oil channels and coolant ducts. The main bearing bores were machined with the block and the lower crankcase, and the main bearing caps had nodular cast iron reinforcements that were cast into the lower crankcase. During final assembly, a liquid gasket was applied between the block and crankcase and they were joined with yield-point tightened bolts;

- A chill-cast aluminium alloy cylinder head;

- Grey iron cylinder liners that were cast-in during the die-cast process for the cylinder block;

- Forged crankshafts made from vanadium-steel that were precipitation hardened (ST: not confirmed for four-cylinder engines);

- Forged connecting rods made from vanadium alloy steel that were precipitation hardened;

- Aluminium pistons with cast-in steel expansion control. The piston ring package consisted of two compression rings and one oil scraper ring;

- Double overhead camshafts driven by a toothed belt with automatic belt tensioner;

- Pent-roof combustion chambers;

- Valves that were actuated by maintenance-free hydraulic tappets. While most N Series engines had four valves per cylinder, some had two valves per cylinder – these engines can be identified by the fifth digit of the engine code (2 for two valves and 4 for four valves);

- Auxiliary units such as alternator, power steering pump and air conditioning compressor (where fitted) were grouped on the left side of the engine for compactness and to protect them from exhaust gas heat. The auxiliaries were powered by a six-groove Poly V-belt.

N Series engine sections

The N Series engines had five major sections (from top to bottom) –

- bearing halves and formed the top part of the cylinder head, while the lower bearing halves were integrated in the cylinder head. The camshaft bores were machined with the camshaft bearing housing and the cylinder head assembled. In final assembly, a liquid sealant was applied between the housing and cylinder head for a tight and stable joint;

- The cylinder head;

- The cylinder block;

- The lower crankcase; and,

- The oil sump.

These five cast aluminium sections were fastened together with bolts and assembled with liquid gaskets.

Modular design, manufacture and construction

As a family of modular engines, the N Series used standardised components that were shared between engines with different configurations (I4, I5 and I6) and capacities. For example, the following components were identical for the B6304F and B5254F engines:

- Pistons, piston rings and gudgeon pins;

- Connnecting rods and bearings;

- Valve guides, seats, springs and tappets;

- The water pump;

- The camshaft drives and covers; and,

- Auxiliary drive and brackets.

Furthermore, the following components were machined in common transfer lines:

- Camshaft bearing housings;

- Camshafts;

- Cylinder heads and blocks;

- Lower crankcases;

- Crankshafts; and,

- Oil pumps.

[su_table responsive=”yes”]

| Badge | Code | Engine | Power | Torque | Models |

|---|---|---|---|---|---|

| 1.8 | B4184S | 1731 cc petrol I4 | 85 kW at 5500 rpm | 165 Nm at 4100 rpm | 1995-99 Volvo S40/V40 1.8 |

| 2.0 10V | B5202S | 1984 cc petrol I5 | 93 kW at 6350 rpm | 170 Nm at 4800 rpm | 1997-98 Volvo S70/V70 |

| B5202FS | 1984 cc petrol I5 | 93 kW at 6350 rpm | 170 Nm at 4800 rpm | 1995-97 Volvo 850, 1997-98 Volvo S70/V70 |

|

| 2.0 20V | B4204FS | 1984 cc petrol I5 | 107 kW at 6500 rpm | 184 Nm at 3800 rpm | 1992-96 Volvo 850 20V |

| B5204S | 1948 cc petrol I5 | 103 kW at 6000 rpm | 183 Nm at 3400 rpm | 1995-00 Volvo S40/V40 2.0 | |

| 2.0 Turbo | B5204T2 | 1984 cc turbo petrol I5 | 132 kW at 5700 rpm | 220 Nm at 2100-5400 rpm | 1996-97 Volvo 850 R, 1997-98 Volvo S70/V70, 1997-98 Volvo C70 |

| 2.3 | B5234FS | 2319 cc petrol I4 | 107 kW at 6500 rpm | 197 Nm at 3700 rpm | 1994-96 Volvo 850 |

| 2.4 | B5254F | 2435 cc petrol I5 | 125 kW at 6100 rpm | 220 Nm at 4700 rpm | 1993-94 Volvo 850 |

| B5254FS | 2435 cc petrol I5 | 125 kW at 6100 rpm | 220 Nm at 4700 rpm | 1996-97 Volvo 850, 1997-98 Volvo S70/V70 |

|

| 2.5 10V | B5252S | 2435 cc petrol I5 | 106 kW at 5400 rpm | 206 Nm at 3600 rpm | 1994-96 Volvo 850, 1997-98 Volvo S70 |

| B5252FS | 2435 cc petrol I5 | 106 kW at 5400 rpm | 206 Nm at 3300 rpm | 1997-99 Volvo S70/V70 | |

| 2.9 | B6304S | 2922 cc petrol I6 | 150 kW at 5200 rpm | 267 Nm at 4100 rpm | 1991-97 Volvo 960, 1997-98 Volvo S90/V90 |

| 2.0T | B4204T | 1948 cc turbo petrol I4 | 118 kW at 5100 rpm | 230 Nm at 1800-4800 rpm | 1998-99 Volvo S40/V40 2.0T |

| B4204T2 | 1948 cc turbo petrol I4 | 118 kW at 5100 rpm | 230 Nm at 1800-4800 rpm | 2000 Volvo S40/V40 2.0T | |

| 2.0T | B5204FT | 1984 cc turbo petrol I5 | 157 kW at 5000 rpm | 300 Nm at 2200 rpm | 1994-97 Volvo 850 2.0T |

| 2.3T | B5234T2 | 2319 cc turbo petrol I5 | 160 kW at 5100 rpm | 330 Nm at 1700-4500 rpm | 1997 Volvo 850, 1997-98 Volvo S70/V70 |

| B5234T7 | 2319 cc turbo petrol I5 | 147 kW at 5000 rpm | 285 Nm at 2000-5000 rpm | 1998-00 Volvo S70/V70 | |

| 2.5 24V | B6254FS | 2473 cc petrol I6 | 130 kW at 5700 rpm | 230 Nm at 4400 rpm | 1995-97 Volvo 960 2.5 24V, 1997-98 Volvo S90/V90 2.5 24V |

| 2.5T | B5254T | 2435 cc turbo petrol I5 | 142 kW at 5100 rpm | 270 Nm at 1800-5000 rpm | 1997 Volvo 850 2.5T, 1997-99 Volvo S70/V70 2.5T, 1998-99 Volvo V70 XC 2.5T, 1998-99 Volvo C70 2.5T |

| 2.5V 20V | B5254S | 2435 cc petrol I5 | 125 kW at 6100 rpm | 220 Nm at 4700 rpm | 1995-97 Volvo 850 2.5 20V, 1997-99 Volvo S70/V70 2.5 20V, 1999 Volvo C70 2.5 20V |

| 3.0 24V | B6304G | 2922 cc petrol I6 | 150 kW at 6000 rpm | 267 Nm at 4300 rpm | 1997-98 Volvo S90/V90 3.0 24V |

| Bi-Fuel | GB5252S | 2435 cc petrol/CNG I5 | 106 kW at 5400 rpm | 206 Nm at 3600 rpm | 1996-97 Volvo 850 Bi-Fuel, 1997-98 Volvo S70/V70 Bi-Fuel |

| GB5252S2 | 2435 cc petrol/LNG I5 | 106 kW at 5400 rpm | 206 Nm at 3600 rpm | 1999 Volvo S70/V70 Bi-Fuel | |

| R | B5234T3 | 2319 cc turbo petrol I5 | 176 kW at 5100 rpm | 330 Nm at 2400-5100 rpm | 1998 Volvo S70/V70 R |

| B5234T4 (manual only) |

2319 cc turbo petrol I5 | 184 kW at 6000 rpm | 350 Nm at 2400-5000 rpm | 1996-97 Volvo 850 R, 1998 Volvo S70/V70 R |

|

| B5234T5 (auto only) |

2319 cc turbo petrol I5 | 179 kW at 5400 rpm | 330 Nm at 2000 rpm | 1996-97 Volvo 850 R | |

| B5234T6 | 2319 cc turbo petrol I5 | 177 kW at 6000 rpm | 310 Nm at 2700-5400 rpm | 1998 Volvo V70 R | |

| B5234T8 | 2319 cc turbo petrol I5 | 184 kW at 5700 rpm | 310 Nm at 2700-5100 rpm | 1999 Volvo V70 R | |

| T4 | B4194T | 1855 cc turbo petrol I5 | 147 kW at 5500 rpm | 300 Nm at 2400-3600 rpm | 1997-00 Volvo S40/V40 T4 |

| T5 | B5204T3 | 1984 cc turbo petrol I5 | 165 kW at 5700 rpm | 310 Nm at 2700-5100 rpm | 1997-00 Volvo S70/V70 T5, 1998-02 Volvo C70 T5, 1997-98 Volvo S80 T5 |

| B5234T3 | 2319 cc turbo petrol I5 | 176 kW at 5100 rpm | 330 Nm at 2400-5100 rpm | 1997-98 Volvo S70/V70 T5, 1997-98 Volvo C70 T5 |

|

| T-5 | B5204T | 1984 cc turbo petrol I5 | 154 kW | 300 Nm | 1994-97 Volvo 850 T-5 |

| B5234T | 2319 cc turbo petrol I5 | 165 kW at 5200 rpm | 300 Nm at 2000-5300 rpm | 1993-96 Volvo 850 T-5 | |

| T-5 R | B5234T5 (manual only) |

2319 cc turbo petrol I5 | 168 kW (over boost: 181 kW) |

340 Nm at 2000 rpm | 1995 Volvo 850 T-5R |

[/su_table]

Volvo Variable Induction System (V-VIS)

As noted above, the Volvo Variable Induction System (V-VIS) was introduced in 1991 in the Volvo 850’s B5254F engine. V-VIS consisted of a conventional plenum chamber that had two parallel inlet ducts to each cylinder that were of different lengths; airflow to the inlet ducts was controlled by a set of electro-pneumatically controlled valves. V-VIS operated as follows:

- If the throttle was more than 80 per cent and engine speed was at 1500-4100 rpm, the valves would close the shorter ducts; and,

- At smaller throttle openings, or at other revs, the valves would remain open and form part of the wall of the short ducts in order to minimise flow losses.

Closing the control valves produced a negative wave – caused by the descending piston and the inertia of the gas in the longer duct – that would accelerate the air column in the duct. At resonance rpm, inertia caused the air to ram into the cylinder just before the inlet valve closed – this resulted in a considerable gain in volumetric efficiency and hence increased torque at medium engine speeds. The valves were made from stainless steel and had soft heat resistant rubber sealing lips which formed a tight seal against the cast wall of the small ducts. With the V-VIS system, 90 per cent of peak torque for the B5254F engine was available from 2000 to 6000 rpm.

Turbocharged engines, however, did not have V-VIS and it is understood that the V-VIS was discontinued after 1994.