[su_image_carousel source=”media: 52210,52211,52212,52213″]

Introduction

A member of the Toyota’s VZ engine family, the 3VZ-FE was a six-cylinder petrol engine with a 60-degree ‘V’ angle. The 3VZ-FE engine was based on Toyota’s 2VZ-FE engine which was first introduced in the Lexus ES 250 (not offered in Australia). For Australia, the 3VZ-FE engine was offered in the Toyota XV10 Camry, the Toyota XV10 Vienta and Lexus XV10 ES 300.

Notwithstanding its relationship to the 2VZ-FE, the 3VZ-FE was originally designed for pick-up trucks and SUVs and is taller than most passenger vehicles engines of comparable capacity. To make the 3VZ-FE fit in the engine bays of front-wheel drive vehicles, the engine was inclined at an angle of approximately 15 degrees. As a result, access to the rear cylinder bank generally requires the intake plenum to be removed.

[su_table responsive=”yes”]

| Engine | Trans. | Years | Peak power | Peak torque | |

|---|---|---|---|---|---|

| Toyota XV10 Camry | 3.0-litre petrol V6 | 4sp auto | 1993-95 | 136kW at 5200rpm | 269Nm at 4400rpm |

| Toyota XV10 Vienta | 3.0-litre petrol V6 | 5sp man., 4sp auto |

1995-97 | 136kW at 5200rpm | 269Nm at 4400rpm |

| Lexus XV10 ES 300 | 3.0-litre petrol V6 | 4sp auto | 1992-96 | 138kW at 5200rpm | 246Nm at 4400rpm |

[/su_table]

3VZ-FE block

The 2959 cc 3VZ-FE engine had a cast iron block with 87.5 mm bores and an 82.0 mm stroke. The 3VZ-FE engine had a deep skirt cylinder block (with a deck height of 223 mm) and interconnected main bearing cradles with two bolt main bearing caps. The 3VZ-FE engine block contained a water jacket through which coolant was circulated to cool the cylinders.

Crankshaft, connecting rods and pistons

The 3VZ-FE had a forged crankshaft that was made of free cutting steel, had nine (9) semi-balance counterweights and operated on four main bearing journals. Furthermore, crankshaft pin diameter was 55 mm, while crankshaft journal diameter was 64 mm.

The 3VZ-FE had cast connecting rods and full-floating type cast pistons.

Cylinder head and valves

The 3VZ-FE had an aluminium alloy cylinder head with a cross-flow type intake and exhaust layout. For the double overhead camshafts (Toyota’s ‘twin cam’),

- The intake camshaft driven by a belt from the crankshaft; and,

- The exhaust camshaft was driven by a scissor gear mechanism that engaged with the intake camshaft.

According to Toyota, this arrangement enabled the valves to be placed at a narrower angle. Lubrication of the cam journals and gears was accomplished by oil being supplied through the oil port in the centre of the camshaft.

The intake valves had a diameter of 34 mm, while the exhaust valves had a diameter of 27.3 mm. Furthermore, intake valve lift was 7.85 mm and exhaust valve lift was 7.60 mm. Both intake and exhaust valves had irregular pitch springs that were made of special valve spring carbon steel, while valve clearance adjustment was achieved by an outer shim type system.

The 3VZ-FE engine had valve overlap of 12 degrees, an intake duration of 230 degrees and exhaust duration of 230 degrees.

[su_table responsive=”yes”]

| 3VZ-FE Valve Timing | ||

|---|---|---|

| Intake | Open | 8° BTDC |

| Close | 42° ABDC | |

| Exhaust | Open | 46° BBDC |

| Close | 4° ATDC | |

[/su_table]

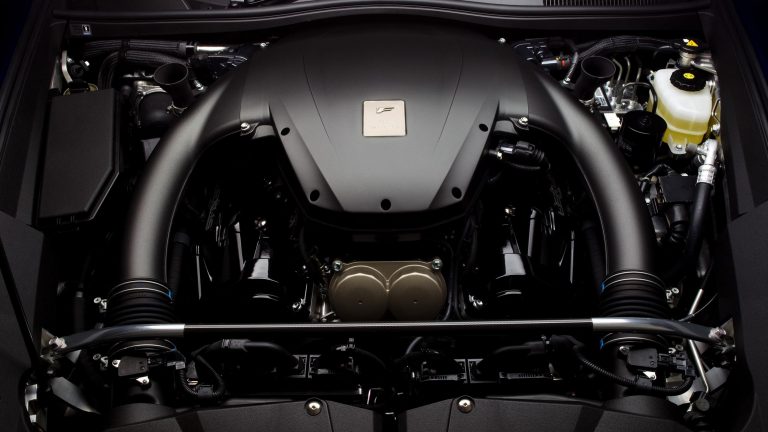

Intake and ACIS

Relative to the 2VZ-FE, the intake port for the 3VZ-FE engine was positioned in an upright position for improved efficiency. The upper intake plenum had a split-chamber design with Toyota’s Acoustic Control Induction System (ACIS) feeding three sets of runners for both heads.

With the ACIS, an intake air control valve within the intake chamber could vary the length of the intake air chamber in two stages according to engine speed and throttle valve opening angle. At lower engine speeds, the induction tract would be extended to improve low-rev torque, while the tract would be shortened at higher engine speeds to improve top-end power.

Injection and ignition

The 3VZ-FE engine had sequential multi-point fuel injection with air supply measured by an L-type hot-wire meter. Furthermore, an oxygen sensor was installed on each bank to provide independent air-fuel ratio measuring and each cylinder bank had a knock sensor. The ignition order for the 3VZ-FE engine was 1-2-3-4-5-6.

With its pent-roof combustion chambers, the 3VZ-FE engine had a compression ratio of 9.6:1.